In this technological world, virtual inventions reached in all field in similar way it had been placed their inventions in manufacturing factories too. A*STAR had build a virtual parts in real manufacturing equipment and this new innovations in factory helps all companies to complete their work faster and quick manner. When it is come to giant manufacturing companies when any one of the strap in the conveyor got failed, then it may lead to millions of loss to the company. Moreover, it is not an easy to task find where the fault is occurred in the conveyor even if they find the exact point of failure, it will take maximum time to diagnose and repair the fault. This time delay is mainly due to the data collections, material and human resources especially when it is a fast moving consumer goods then these delay would leads to lose their reputation in deliver goods. In digital twins is an advanced technology in manufacturing field it includes intelligent machines with fully sensorized.

How the twin digitals would make factories better?

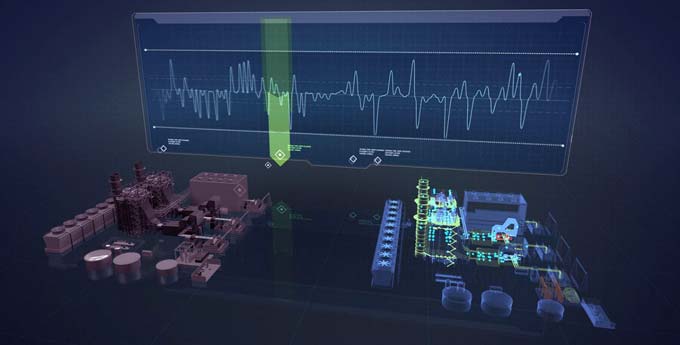

The main idea behind the twin digital is all the machines are sensorized like wise when many machines are sensorized together. The spindle in each machine will monitor all the sensorized machines performance and sent the data’s to the central control room. In order to have all these single computer in central control room is fed by data to act as a twin digital. The virtual copy of data fed to the central computer reflects accurate operating of the machine based on the real time sensor placed in the machines. All these avoid maintenance cost and time involved in repairing each machine moreover in case if any fault occur the sensor send a virtual data to the center computer which in turn helps to recover the fault in earliest.

The most challenging work in this digital twin technology is to make sensorised machines and inter connect them to centralized control room. While saying sensorised machines it does not meant that only single sensor is fixed to machine in real totally 43 sensors are fixed within the machine. Theses sensors sense the machine vibration, machine temperature and their output rates at delivers accurate data of machine performance to the control system.

Removal of human resources:

The digital twin technology is mainly designed with robotic designs which can handle the manufacturing company and virtually assist the human resources. This technology made entire human resources just to monitor the work and to check all the processes are functioning in normal way. Although the data information is send to central computer in addition it also has option to handle physically. More over the digital twin machines are designed to act as bidirectional device so the machines can automatically adjust its physical twin operations based on the digital data’s they receive.

Present digital twin factory:

At present this technology is used in two manufacturing companies in Singapore ARTC and SIMTech. These two companies plays a vital role in using advanced technology for business purpose the main features of the digital twins used in their factories are listed below.

- All machines have connected sensors within them.

- Entire information about factory is collected to the central control room and represented visually.

- The digital twin machines control machines by predicting the error via sensor.

- If mobile data fails the technology assist maintenance and repair the error without human help.

All the above features make the technology more secure, safe and reliable to use them in companies. While using this technology the main work of humans is to monitor where machine talk to machine to complete the work with more efficient way.